| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Yushun

Model Number : Customized

Certification : ISO9001

Place of Origin : Jiangsu, China

MOQ : 1

Price : CNY 100000

Supply Ability : 1 Set 60 days

Delivery Time : 0-60 days

Packaging Details : Safety Seaworthy Package

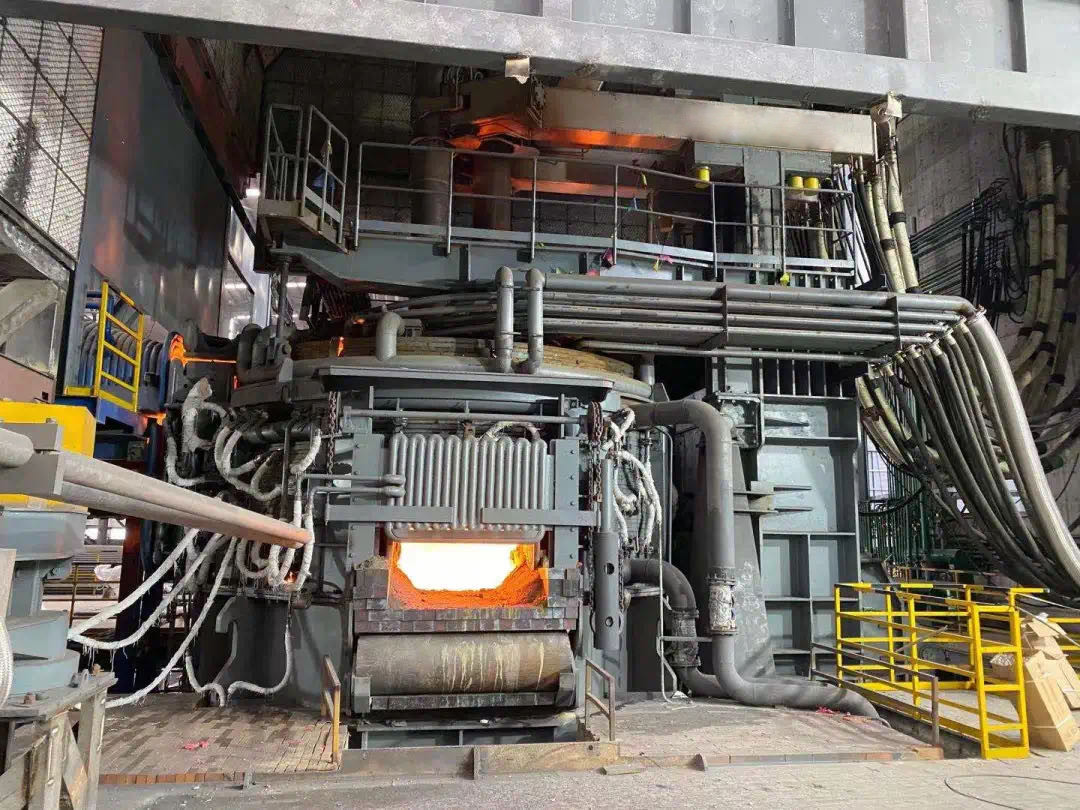

Name : 10 ton Industrial Steel Smelting Furnace Electric Arc Furnace (EAF)

Specification : 10T

Type : Steel making equipment

Power : 50KW-5000KW

Voltage : Depending on production

Usage : Melting furnace and steel casting

Size : Customized

Feature : Accurate temperature control

10 ton Industrial Steel Smelting Furnace Electric Arc Furnace (EAF)

Electric arc furnace is an electric furnace that smelts metal and ore at high temperature by electric arc of electrodes.The energy of gas discharge arc is very concentrated, and the temperature of arc area is above 3000℃.For smelting metal, electric arc furnace is more flexible than other steelmaking furnaces, and can effectively remove impurities such as sulfur and phosphorus. The furnace temperature is easy to control, and the equipment occupies a small area, so it is suitable for smelting high quality alloy steel.

Features

| 1) Fast smelting with low production cost |

| 2) low-pollution and environment-friendly |

| 3) A direct effect from the cold furnace melting. |

| 4) Power adjustment flexibility. |

| Place of origin: | Jiangsu, China |

| Condition: | New |

| Specification: | 2T-80T |

| Type: | Steel making equipment |

| Voltage: | Depend on production |

| Dimension(L*W*H) | Customized |

| Certification: | ISO9001 |

| Weight(T): | 150T |

| After-sales Service: | Field installation, commissioning and training, field maintenance and repair service |

| Warranty: | 1year |

Electric arc furnace through the graphite electrode into the electric arc furnace, the electric arc between the electric end and the charge as the heat source for steelmaking.Electric arc furnace takes electric energy as heat source and can adjust the atmosphere in the furnace, which is very beneficial to smelting steel containing more easily oxidized elements.Using high temperature flue gas of electric furnace can preheat raw materials through technology and equipment, in order to achieve high efficiency, energy saving, environmental protection, high yield.With the improvement of electric arc furnace equipment and smelting technology, the development of power industry, electric steel of lower costs, and now the electric furnace is not only used in the production of alloy steel, and a large number of used to produce ordinary carbon steel and iron concentrate pellets direct smelting, the proportion of the output of steel smelted by electric arc furnace in the total output of domestic steel is rising.

Our Technology

1. High power

Ultra-high power technology is the focus of our research. Ultra-high power is the most prominent feature of the new generation of EAF equipment. The advanced steel-making technology of electric furnace ensures the highest level of productivity and quality.As a result, EAF capacity has been greatly increased.

2. High efficiency

EAF uses new scrap preheating technology to minimize production costs, increase production and meet environmental standards.The energy consumption per ton of steel is reduced to below 280kWh through 100% scrap preheating and effective recovery and utilization of heat energy. The modern EAF smelting efficiency is greatly improved by adopting horizontal preheating or scrap preheating technology on furnace top, oxygen lance technology on furnace door and furnace wall, slag foam technology and automatic electrode connection technology.

3. High quality

Combined with LF, VD, VOD and other equipment, EAF can smelt and produce high quality steel or stainless steel. Super high power input and high production capacity are the unique features of this furnace smelting.

4. High flexibility

Rely on the development of the decades of electric furnace of rich experience, we can provide all kinds of advanced and efficient solution for EAF steelmaking, including various specifications and types of electric arc furnace, such as casting with a slot arc furnace steel, top charging electric arc furnace, horizontal continuous charging electric arc furnace, furnace top arc preheating furnace, ferroalloy electric furnace, stainless steel electric arc furnace,As well as the related process, automation and environmental protection system, the advanced oxygen blowing and carbon injection technology strengthens the EAF smelting performance.Oriental Huachuang arc furnace is the ideal smelting equipment for all kinds of steel from carbon steel to high alloy steel and stainless steel.

Selling Units: Single item

Single package size: 150*100*170cm

Single gross weight: 100,000kg

Package Type: Safety Seaworthy Package

Lead Time:

| Quantity (Tons) | 1-100 | >100 |

| Est. Time(Days) | 60 | To be negotiated |

|

|

10 Ton Steelmaking Electric Arc Furnace Images |